When a light refuses to glow, a motor sputters, or an entire system goes dark, it's easy to feel lost in a tangle of wires and components. But what if you had a clear, precise roadmap to navigate that complexity? That's precisely what troubleshooting with circuit diagrams offers: a powerful, indispensable tool that transforms guesswork into guided diagnosis, allowing you to pinpoint electrical faults with confidence and precision.

Think of a circuit diagram not just as a schematic, but as the DNA of an electrical system. It reveals its structure, its function, and the intricate pathways of current. For anyone from a DIY enthusiast tackling home repairs to a seasoned technician diagnosing complex industrial machinery, mastering the art of reading and utilizing these diagrams is the ultimate superpower. It’s how you move from merely observing a symptom to understanding its root cause, and more importantly, how you fix it safely and effectively.

At a Glance: What You'll Master Here

- Deciphering Circuit Diagrams: Learn to read these essential electrical blueprints.

- Your Troubleshooting Toolkit: Understand the crucial instruments for diagnosis.

- A Step-by-Step Fault-Finding Strategy: A systematic approach to uncover problems.

- Diagnosing Common Electrical Faults: Recognize and resolve frequent issues like open circuits, shorts, and overloads.

- Advanced Diagnostic Principles: Go beyond the basics with insights into voltage drop, continuity, and the "divide and conquer" method.

- Safety Protocols: Non-negotiable rules to keep you safe while working with electricity.

Why Circuit Diagrams Aren't Just for Pros: The Roadmap You Need

Every electrical system, from your car's stereo to a home's lighting circuit, is designed with a specific purpose and structure. Without a map of that structure, identifying why something isn't working is like trying to navigate a new city without GPS or a physical map – you're reliant on trial and error, which in electrical work, can be dangerous and costly.

Circuit diagrams provide that essential roadmap. They abstract the physical chaos of wires into a clean, logical representation using standardized symbols. With this visual guide, you can trace the intended path of electricity, identify components, understand their relationships, and, crucially, predict where problems might arise. This isn't just about repair; it's about verifying correct installations and preventing future issues. To truly understand the heart of any electrical problem, you first need to be adept at Mastering circuit diagrams themselves.

Before You Begin: The Essential Toolkit for Electrical Sleuths

Just as a detective needs their magnifying glass and notebook, you'll need specific tools to effectively troubleshoot an electrical circuit. These aren't just gadgets; they're extensions of your senses, allowing you to "see" electricity in action.

- Multimeter: This is your primary diagnostic tool. It measures voltage (potential difference), resistance (how much a component opposes current), and continuity (whether a circuit path is complete). A good digital multimeter is precise, versatile, and often includes features like frequency or capacitance measurement. To get the most out of it, you'll want to focus on mastering your multimeter.

- Test Lamp/Voltage Tester: A simple tool that quickly indicates the presence of voltage. While not as precise as a multimeter, it's excellent for rapid checks at various points to confirm if power is present or absent.

- Clamp Meter: This specialized meter measures current (amperage) without requiring you to disconnect wires. You simply clamp it around a single conductor, making it invaluable for diagnosing overloads or unexpected current draws in live circuits, though caution is paramount.

- Insulation Tester (Megohmmeter): Used to check the integrity of wire insulation and detect leakage currents or incipient short circuits by applying a high DC voltage and measuring the resulting current. This is more common in industrial or commercial settings for preventative maintenance.

- Wiring Diagram Reference: The most crucial "tool" of all. Always ensure you have the correct, up-to-date diagram for the specific system you're working on. An outdated or incorrect diagram is worse than none at all, leading you down wrong paths.

Safety First: Non-Negotiable Rules of Engagement

Working with electricity carries inherent risks. Before you even pick up a tool, commit these safety precautions to memory and practice them religiously. They are not optional; they are life-saving. For a deeper dive into these protocols, be sure to review critical electrical safety practices.

- De-energize: Always, always turn off the power at the circuit breaker or fuse box before touching any wires or components. Verify the power is off using your multimeter or test lamp.

- Lockout/Tagout (LOTO): For industrial or commercial settings, implement proper lockout/tagout procedures to prevent accidental re-energization.

- Insulated Tools: Use tools with insulated handles to protect against accidental contact with live circuits.

- Personal Protective Equipment (PPE): Wear appropriate PPE, including safety glasses to protect against arc flashes or flying debris, and insulated gloves when required.

- Never Bypass Safety Devices: Fuses and circuit breakers are there for a reason. Never replace a fuse with one of a higher rating or bypass a breaker. This creates a severe fire and shock hazard.

- Follow the Diagram: Adhere strictly to the wiring diagram. Deviating from it can lead to confusion, damage, or unsafe conditions.

- Work One-Handed (When Possible): If you must work on a live circuit (e.g., measuring voltage), try to work with one hand, keeping the other in your pocket or behind your back. This reduces the chance of current passing through your chest and heart if you accidentally complete a circuit.

Decoding the Map: Understanding Your Circuit Diagram

Before you can troubleshoot, you must comprehend the language of the diagram. It’s a visual shorthand, using symbols to represent components and lines to represent wires. Learning understanding circuit diagram basics is your first crucial step.

- Identify the Power Source: Locate where the electricity enters the circuit (e.g., battery, power supply, utility line). This is usually clearly marked.

- Trace the Main Path: Follow the lines (wires) from the power source through protective devices (fuses, circuit breakers). These are typically the first components encountered after the power source.

- Recognize Components: Identify switches, relays, resistors, capacitors, motors, lamps, and other loads using their standard symbols. The diagram will often include a legend or component list.

- Understand Connections: Solid lines denote physical wires. Junctions where lines connect are usually indicated by a dot. Lines that cross without a dot are typically not connected.

- Locate Ground Points: Find where the circuit connects back to ground or neutral. This completes the circuit path. A robust ground is essential for safety and proper operation.

- Note Ratings and Values: Look for labels indicating voltage, current, resistance, or component values. These are critical for checking against actual measurements.

By systematically examining these elements, you build a mental model of how the circuit should operate, which is the foundation for finding what's wrong.

Your Blueprint for Problem-Solving: A Step-by-Step Troubleshooting Strategy

With your diagram understood and tools ready, it's time to adopt a methodical approach. This strategy prevents aimless probing and guides you directly to the fault.

1. Identify and Understand the Symptoms

What exactly is the problem? Is a device completely dead? Does it work intermittently? Is there smoke, unusual smells, or strange noises? The more specific you can be about the symptom, the better you can narrow down potential causes.

- Example: "The kitchen lights aren't working, but the outlets are fine." This immediately suggests the problem is isolated to the lighting circuit, not the main power supply to the kitchen.

2. Start with the Power Source (and Protection)

Before delving into complex circuits, confirm the basics.

- Verify Input Voltage: Using your multimeter, check for voltage at the main input of the problematic circuit, as indicated on your diagram.

- Check Fuses/Breakers: If no voltage, check the corresponding fuse or circuit breaker. A blown fuse or tripped breaker is a clear indicator of a problem, often an overload or a short circuit. Reset a breaker once, or replace a fuse, but if it trips/blows again immediately, there's an underlying fault that needs addressing.

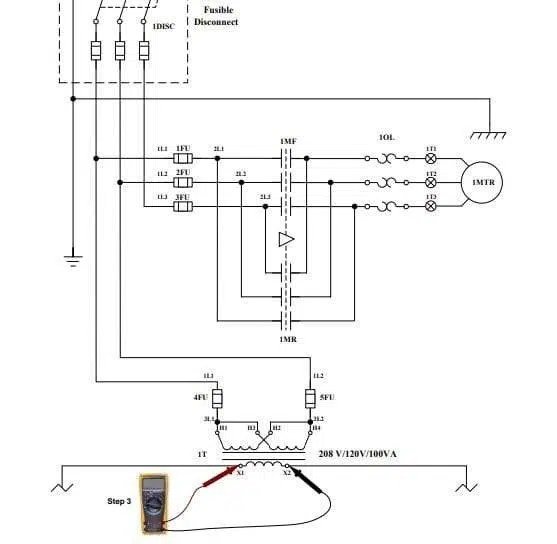

3. Trace the Path: Divide and Conquer

This is where the wiring diagram truly shines. Follow the current path from the power source towards the load, taking voltage measurements at key points.

- Work Systematically: Begin at the power source and move along the diagram's depicted current path. Test for voltage before and after each major component (switches, relays, loads).

- Look for Voltage Drops: A significant voltage drop across a component that shouldn't have one (like a switch in the ON position) indicates high resistance or an open circuit.

- The "Divide and Conquer" Strategy: For longer, more complex circuits, pick a point roughly halfway between the power source and the load. If you have voltage there, the problem is downstream. If you don't, it's upstream. This halves your search area with each check, rapidly isolating the fault.

4. Check the Ground Connection

Many problems are due to a faulty or absent return path.

- Verify Continuity to Ground: With the power off, use your multimeter's continuity or resistance setting to check for a good connection between the ground point shown on the diagram and a known good ground (like a metal conduit or the main ground bar). A high resistance reading or open circuit indicates a problem.

- Look for Corrosion: Loose or corroded ground connections are notorious for causing intermittent issues, dimming, or erratic behavior.

5. Test Components Individually

Once you've narrowed down the general area, you might need to test specific components.

- Isolate and Test: Often, this means disconnecting the component from the circuit (ensuring power is off!) and testing it with your multimeter. For example:

- Switches: Check for continuity when ON, open when OFF.

- Resistors: Measure their resistance and compare to the diagram's stated value.

- Relays: Test the coil for resistance and the contacts for continuity when energized (carefully, or with an external power source).

- Loads (e.g., motors, heaters): Check their resistance. An open circuit (infinite resistance) means the component itself has failed internally.

6. Isolate, Repair, and Retest

Once the faulty component or section is identified:

- Replace/Repair: Replace the faulty component with an identical one, or repair the damaged wiring.

- Re-Test: Reconnect everything, restore power, and retest the system to ensure the fault is resolved and no new problems have been introduced.

The Usual Suspects: Common Electrical Faults & How Diagrams Expose Them

Understanding the typical culprits behind electrical problems helps you anticipate and diagnose issues more quickly, especially when you're comparing your measurements to the values specified in the wiring diagram.

Open Circuits: The Invisible Break

- Symptoms: The device or entire section of the circuit is completely dead (no power, no function).

- Diagnosis with Diagram: An open circuit is a break in the current's path. The diagram shows the intended path. Use your multimeter in continuity mode (power off!) or voltage mode (power on, carefully) to trace the circuit.

- Continuity Check: Go point-to-point along the diagram, checking for continuity. Where continuity stops, that's your open. This could be a broken wire, a loose connection, a blown fuse, an open switch, or an internal component failure.

- Voltage Check: If you measure full voltage before a point, but zero voltage after it, you've found the break. For instance, you might read full voltage across an open switch's terminals if it's supposed to be closed, but nothing on the load side.

Short Circuits: The Fuse Killer

- Symptoms: Immediate fuse blowing or circuit breaker tripping upon power-up, often accompanied by sparks, smoke, or a burning smell. A diagnosing a short circuit article provides a detailed method for resolving this issue.

- Diagnosis with Diagram: A short circuit occurs when current bypasses its intended path and finds an unintended, low-resistance path, usually directly to ground or neutral. This causes dangerously high current flow.

- Look for Direct Paths: The diagram shows the intended current flow. Mentally (or physically) look for any place wires could be touching where they shouldn't, or where insulation is damaged.

- Resistance Check (Power Off): Disconnect the power and use your multimeter in resistance (Ohms) mode. Look for abnormally low resistance (close to 0 Ohms) between a "hot" wire and ground/neutral, or between two wires that should be isolated.

- Disconnect Sections: If you suspect a short, disconnect sections of the circuit as shown on the diagram and test them individually. When the fuse stops blowing, you've isolated the problematic section.

Overloads: When Too Much is Too Much

- Symptoms: Circuit works temporarily, then the breaker trips or fuse blows, but only after some time. It's often related to too many devices drawing power simultaneously.

- Diagnosis with Diagram: An overload happens when the total current drawn by connected loads exceeds the rating of the fuse, breaker, or wire.

- Check Ratings: Compare the current ratings of fuses, breakers, and wire gauges (often noted on the diagram) against the total current draw of all connected loads.

- Clamp Meter: Use a clamp meter to measure the actual current flowing through the circuit. If it consistently exceeds the breaker's or wire's rating, you have an overload. The solution is to reduce the load or re-evaluate the circuit design for additional capacity.

Faulty Switches or Relays: The Intermittent Culprits

- Symptoms: Device works intermittently, not at all, or remains stuck ON/OFF.

- Diagnosis with Diagram: Switches and relays are control devices. The diagram shows their position in the circuit and their contacts.

- Continuity Test (Power Off): Disconnect power and test the switch or relay contacts with your multimeter for continuity. A switch should show continuity when ON and an open circuit when OFF. A relay's coil should have a measurable resistance. Its contacts should change state (open to closed, or vice versa) when the coil is energized (safely test with an external, low-voltage supply if possible).

- Voltage Test (Power On): Measure voltage on both sides of the switch/relay when it's supposed to be in the "on" state. If you have voltage on one side but not the other, the switch/relay is faulty internally.

Poor Ground Connections: The Unstable Foundation

- Symptoms: Dim lights, motors running weak or erratically, unpredictable circuit behavior, or even a slight tingle when touching metal objects.

- Diagnosis with Diagram: The diagram clearly shows ground connections. A poor ground connection increases resistance in the return path, reducing the voltage available to the load.

- Resistance/Continuity Check (Power Off): Measure resistance between the component's ground connection point (as shown on the diagram) and a verified good system ground. High resistance indicates a poor connection.

- Visual Inspection: Look for loose, corroded, or broken ground wires at terminal blocks, component chassis, or junction points. Corrosion is a common culprit.

Beyond the Basics: Advanced Diagnostic Principles

Seasoned troubleshooters leverage fundamental electrical principles to interpret their measurements and strategize their approach.

Voltage Drops and What They Tell You

Voltage is the "pressure" that pushes current. When current flows through a resistance, a voltage drop occurs across that resistance.

- Normal vs. Abnormal Drops: Your diagram helps you anticipate normal voltage drops (e.g., across a motor or a resistor). An unexpectedly high voltage drop across a supposedly low-resistance point (like a wire, connector, or a closed switch) is a red flag indicating abnormally high resistance there. This could be corrosion, a loose terminal, or a damaged wire.

- Open Circuit Voltage: In an open circuit, if you measure voltage across the break itself (e.g., across a blown fuse or an open switch), you will often read the full source voltage. This is because no current is flowing, so there's no voltage drop anywhere else in the circuit, and the multimeter effectively measures the potential difference across the open gap.

Electrically Common Points: Your Continuity Check

Points directly connected by a continuous wire (with negligible resistance) are considered "electrically common."

- Expected Behavior: In a healthy circuit, there should be virtually zero voltage difference between any two electrically common points.

- Diagnostic Power: If you measure any significant voltage between two points that the diagram shows are directly wired together, it means there's an open circuit, high resistance, or a fault between those two points. This technique is incredibly powerful for identifying breaks in wiring or bad connections.

The "Divide and Conquer" Mentality

We touched on this earlier, but it bears repeating. This is perhaps the most efficient troubleshooting technique for complex circuits.

- Process: Identify the entire circuit path on your diagram. If the whole circuit is dead, start at the source. If only a specific part is affected, focus there. Measure at the halfway point.

- If the first half has power, the problem is in the second half.

- If the first half has no power, the problem is in the first half.

- Repeat: Continue halving the problematic section until you isolate the single component or wire causing the issue. This systematically eliminates large portions of the circuit from consideration.

Mastering Your Multimeter for Precise Readings

Your multimeter is only as good as your understanding of its functions and limitations. Ensure you're selecting the correct function (Volts, Ohms, Amps) and range for your measurement. For detailed guidance, revisit mastering your multimeter.

- Voltage Measurement: Always measure voltage in parallel with the component or circuit you're checking.

- Resistance Measurement (Ohms): Always measure resistance with the power off and the component isolated from the circuit if possible. Measuring resistance in a live circuit or one with parallel paths will give inaccurate results. When interpreting ohmic values, remember that zero ohms means a direct connection (short), and infinite ohms means an open circuit.

- Current Measurement (Amps): Usually requires the multimeter to be inserted in series with the circuit (which means breaking the circuit to insert the meter) or using a clamp meter. This is why clamp meters are often preferred for their non-invasive nature.

Fault Elimination: Sharpening Your Focus

Given a specific set of symptoms, use your circuit diagram and understanding of circuit analysis to:

- List Possible Faults: Based on the symptoms and the diagram, brainstorm all plausible causes.

- Eliminate Impossible Faults: Rule out causes that don't fit the symptoms. For example, if a fuse isn't blowing, a hard short is less likely than an open circuit or a faulty component.

- Prioritize Likely Faults: Start testing for the most common or easiest-to-check faults first.

Pitfalls to Avoid & Pro Tips for Troubleshooting Success

Even with the best tools and diagrams, troubleshooting can throw curveballs. Here's how to stay sharp:

- Don't Rush: Impatience leads to mistakes and potential hazards. Take your time, think through your steps.

- Avoid "Shotgunning": Don't just replace parts randomly hoping to stumble upon the fix. This is costly and inefficient. Use your diagram and measurements to guide your replacements.

- Verify Your Diagram: Especially with older systems or modified equipment, diagrams can become outdated. If readings don't make sense, consider if the diagram accurately reflects the current system.

- Check the Obvious First: Is it plugged in? Is the power switch on? Is the breaker tripped? These simple checks often save hours of complex diagnosis.

- Document Everything: Keep a troubleshooting journal. Note symptoms, steps taken, measurements, conclusions, and repairs. This is invaluable for complex or intermittent problems and helps you build your expertise. For team efforts, it's non-negotiable.

- Look for Visual Cues: Before you even touch your meter, look for scorched components, frayed wires, loose connections, or corrosion. Many problems are visible.

Empowering Your Electrical Detective Skills

Troubleshooting with circuit diagrams isn't just a technical skill; it's a mindset – a blend of logic, patience, and a deep respect for electrical principles. By leveraging these essential roadmaps, you're not just fixing a broken device; you're developing an understanding of how complex systems work, building confidence, and ensuring safety in every electrical endeavor.

So, the next time an electrical mystery arises, remember your diagram, grab your multimeter, and approach the problem like the seasoned electrical detective you're becoming. You have the tools, the knowledge, and the map to pinpoint that fault and bring your circuits back to life.